FSC 6FT X Bammax Fumigated Pallet Patio Fencing Outdoor Fence

Basic Info

| Model NO. | ZYJX-F-01 |

| Surface Treatment | Sanding/ Embossing/ Brushing |

| Panel Density | 1.2 Kgs~ 1.35 Kgs/ Cm3 |

| Panel Water Absorption Rate | Less Than 2% |

| Working Environment | -40~60 Degrees Celsius |

| MOQ | 100 Sets |

| Lead Time | 20 Day |

| Features | Windproof, Waterproof, UV Stable |

| Colors | Grey, Brown, Coffee or Customized |

| Fire Rating | Class B |

| Sample Availability | Yes |

| Sample Ready Time | 2 Working Days |

| Basement Option | Longer Post or Iron Base |

| Optional Post | Composite Wood Post |

| Optional Size | Can Be Customized |

| Panel Board Material | Wood Plastic Composite |

| Transport Package | Fumigated Pallet |

| Specification | 1.8x1.8 m |

| Trademark | Bammax |

| Origin | China |

| HS Code | 39189090 |

| Production Capacity | 20000 Sets/ Month |

Product Description

Weather resistant veranda terrace patio waterproof anti-aging plastic wood grain WPC composite fence panelProduct features:

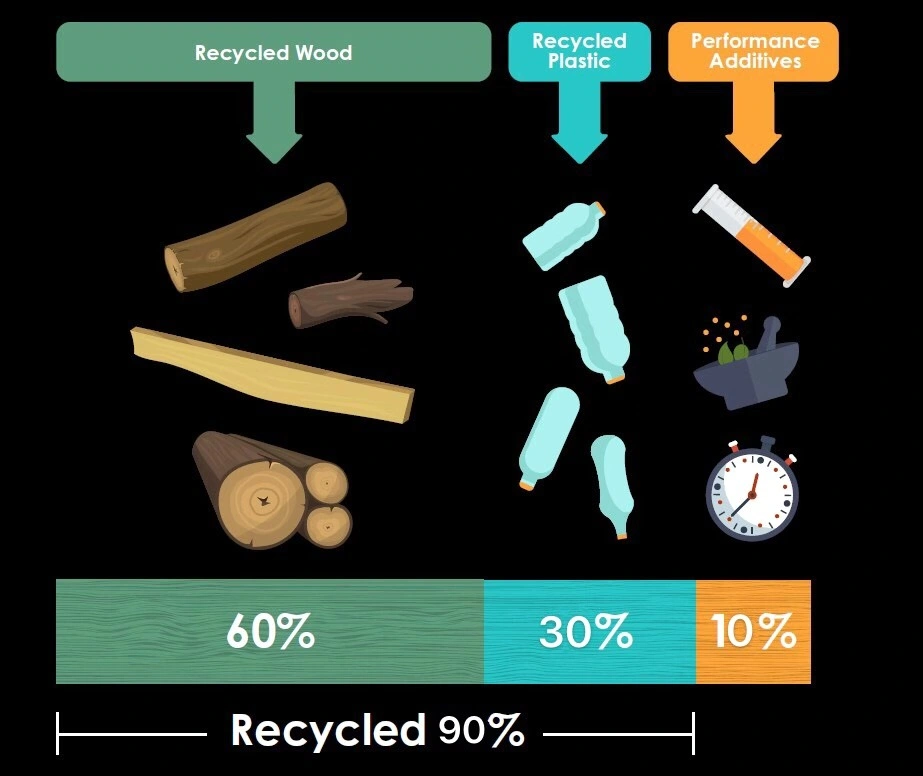

1. Made of recycled plastic (HDPE) and wood powder, plus non-hazardous chemical additives such as anti UV agent, light stabilizer, lurbicant, culping agent and etc, our Composite fencing gives any fencing panel a fantastically clean and professional finish.

2. Designed against fading has anti mildew properties and is anti slip even when wet. The full bodied colour means that the wall cladding can be sanded down like traditional wood whilst maintaining its original colour.

3. Profiles adjustable, lengths adjustable, colors adjustable, surface treatment adjustable

4. Treads on surface of our WPC fencing provide a choice of desirable, tough anti-slip surfaces. The vivid wood grain look makes it more natural to see and feel. The boards have self-cleaning anti mildew construction and require virtually no maintenance for their life.

5. Easy intallation and cost efficiency

Product information:

| Material composition | 60% Wood+ 30% HDPE+ 10% Additives |

| Product profiles | Square |

| Surface treatments | Sanding, Embossing, Brushing, Smooth |

| Product finishes | Online embossed/ Co-extruded/ Classic |

| Available posts | WPC post or aluminum post |

| Popular sizes | 1.8x1.8m, 2x2m |

| Popular colors | Teak, Grey, Brown, Coffee |

| Approximate loading qty | 200 sets / 1x20ft container |

| Applications | Commercial or personal, home and garden, Landscaping |

| Adavtanges over timber | Long life span, eco friendly, recyclable |

FAQ:

1. What's WPC?

WPC is short for Wood Plastic Composite. The combination of the raw materials are mostly 30% recycled plastic (HDPE) and 60% wood powder, plus 10% additives such as anti-UV agent, lubricant, light stabilizer and etc.

2. What's the process to make WPC fencing?

(a) Mix raw materials according to certain formula, then make them into pellets.

(b) By extrusion machine and mold, shape the products in customized profile and size.

(c) Do surface treatment such as sanding or embossing, then cut the WPC fencing by requested length before package.

3. What are the benefits to use composite fencing?

(a) Composite fencing is waterproof, fire retardant, UV resistant, anti-slip, maintenance free and durable.

(b) Its profiles, lengths, colors, surface treatments are adjustable.

(c) It's easy to install and cost efficient.

(d) Since the raw materials are recycled, the product itself is eco-friendly.

4. What colors are available?

5. Why us?

Zhengyuan WPC is a leading supplier of composite products with over 10 years' experience in producing durable, performance-improving and cost-effective composite solutions to a wide range of industries. We help companies of all sizes unlock the power of composite products, and our client base includes businesses in the Industrial, Construction, Rail, Transport, Landscaping, Marine and Leisure sectors. There are reasons we believe to make us a qualified, satisfied and better supplier to our clients:

(a) By more than 30 extrusion lines, we are able to ship out more than 100 containers per month.

(b) 30% of our annual profits would be invested in R&D, which enables us to obtain much more experience in composite products' upgrade than our competitors. For each year we launch new products in different product categories, which provides our clients with more options.

(c) Based on our marketing research, we are confident to offer our clients competitive prices based on reliable qualities. We have our client base growing by 20% year on year.

(d) We have our products tested by third parties, such as SGS, TUV and Intertek to issue formal quality testing reports and we assure our clients of punctual lead time. We are proud of our sales network having extended to more than 60 countries all over the world, and it keeps growing.

(e) We care a lot about sales& service. From start to finish, our sales representatives, installation builders and after-sales attendants are always ready of service. For any question regarding any aspect of the composite products we can provide you professional advice and solutions. With honesty and sincerity, we are looking forward to this mutual cooperation with your company.

Company profile:

Certifications:

Exhibition:

Projects:

One huge advantage that composite material has over conventional wooden material is that it requires very little in maintenance.

The plastic component found in a composite board means that it isn't susceptible to wood rot, dampness and pests. Unlike a wooden plank, they don't need to be treated, sealed, stained or painted, and aren't at risk of twisting and warping due to sun exposure or water absorption. Furthermore, they won't fade like timber wood does should they experience exposure to these elements.

Thanks to their composition, the composite fencing will also serve the homeowner for a much longer period of time, typically outlasting a wooden fencing by up to 5-10 years in the lifespan department, with some ranges even coming with a 15-25 year guarantee warranty insuring the investment of your money in this product.

It is true that the initial outlay for a composite fencing is slightly more expensive than that of a wooden fencing, but what you fork out in the short term will virtually pay for itself in the long term, because composite decks require nothing in terms of maintenance and never age in appearance, unlike timber wood which require regular upkeep and are always at risk of fading and losing their brilliant looks.